Welcome! Becoming a registered user of ShortWingPipers.Org is free and easy! Click the "Register" link found in the upper right hand corner of this screen. It's easy and you can then join the fun posting and learning about Short Wing Pipers!

-

Re: Here or Maintenance? Engine quit on final.

Re: Here or Maintenance? Engine quit on final.

Originally Posted by

Subsonic

I think you need more heat. Oil temp should get above 212 degrees F. The boiling point of water. Cover your oil cooler, if you have one. I don't know about these engines in these planes, but I know you need more heat. Sure, you can run richer, but if you run it rich at low combustion temp you're going to introduce carbon condensation and spark plug fowling next, if you don't have enough combustion heat. You need another 100 degrees more heat. That will fix most of your problem.

If you had to get everything above the boiling point of water to vaporize it most things in our world would never dry. Especially in Florida in the summer.

Once you get the temperature above the dew point temperature water starts to evaporate. The greater the dew point spread between the dew point and the sensible temperature the faster the water vaporizes.

Ever seen ice evaporate without transitioning to water? It’s the temperature and pressure where water can exist as a liquid, solid and a gas simultaneously. It’s called the triple point and happens all the time in Wisconsin in the winter.

Granted it’s nice to have the oil temperature at 165F or more for rapid water vapor removal.

Last edited by Gilbert Pierce; 12-03-2021 at 08:45 PM.

-

Re: Here or Maintenance? Engine quit on final.

Re: Here or Maintenance? Engine quit on final.

I had one of those weird, serendipitous moments when a random guy walked past my hanger today, stopped and said "You aren't flying that thing without covering at least part of the cowling openings, are you?"

So we chatted a bit. He has a Pacer (nope he's never heard of shortwing.org) and says he covers a little less than half of each opening with duct tape when the temperature drops below 30 degrees.

It's cheap and easy. When the weather clears, I'll give it a go.

-

Re: Here or Maintenance? Engine quit on final.

Re: Here or Maintenance? Engine quit on final.

Originally Posted by

Gilbert Pierce

if you had to get everything above the boiling point of water to vaporize nothing in our every gay world would ever dry.��

Agree! When exposed to normal atmospheric pressure in a free air - one atmosphere environment, you're absolutely correct. A partially vented engine crankcase is not that, however. It provides pressurization and containment that keeps water from easy escape to the atmosphere. Like a terrarium where you grow plants in a bottle. The water just keeps condensing at the top and recycling by raining or running down the walls of the crankcase back to the oil if you don't boil it off. That crankcase containment limits the evaporation of water out of the case at lower temperatures and pressures. The water condenses and drops back into the oil. Look at your tea kettle. How much venting of moisture happens below the boiling point. Very little, I think. It could take days or weeks to evaporate a tea kettle at 110 deg. F. I can do it in a half hour if I ignore the shrieking of the kettle once its boiling. I think his engine quit running when he chopped power on final because it wasn't very warm, and his carb froze the water in the venturi. His engine needs more heat everywhere.

-

Re: Here or Maintenance? Engine quit on final.

Re: Here or Maintenance? Engine quit on final.

During the cooler months I have to takeoff with carb heat in the Cub on or it stumbles real bad on takeoff roll. There are 2 fixes I have known about for a few years. The first is to seasonally adjust the idle mixture and the other is to install the plate over the intake filter. The Stromberg carbs are especially prone to ice and seasonal mixture issues. I should do both but I never think about it when I am in a position to do anything about it.

BTW, stock J3’s hardly ever get the oil hot enough. Even on he hottest summer day.

-

Re: Here or Maintenance? Engine quit on final.

Re: Here or Maintenance? Engine quit on final.

Flying in Michigan here with winter kit over oil cooler. 18 Fahrenheit outside and Oil temps stabilized at 150. I don’t have a CHT gage. Never worried about it until this thread. Should I tape part of the cowl inlets? If so what part. Top, bottom inside outside?? I like to do pattern work, so lots of low power settings. Am I damaging my engine ? -Brian in Owosso

-

Re: Here or Maintenance? Engine quit on final.

Re: Here or Maintenance? Engine quit on final.

Originally Posted by

brian heidt

Flying in Michigan here with winter kit over oil cooler. 18 Fahrenheit outside and Oil temps stabilized at 150. I don’t have a CHT gage. Never worried about it until this thread. Should I tape part of the cowl inlets? If so what part. Top, bottom inside outside?? I like to do pattern work, so lots of low power settings. Am I damaging my engine ? -Brian in Owosso

If you fly for an hour or more each time you light it off, you're probably getting rid of most of the water if you get your oil temps up around 200F or more.

I wouldn't recommend taping up your cowl inlets, but it's not a bad idea IMO. I'd use more RPM and fly the plane harder.

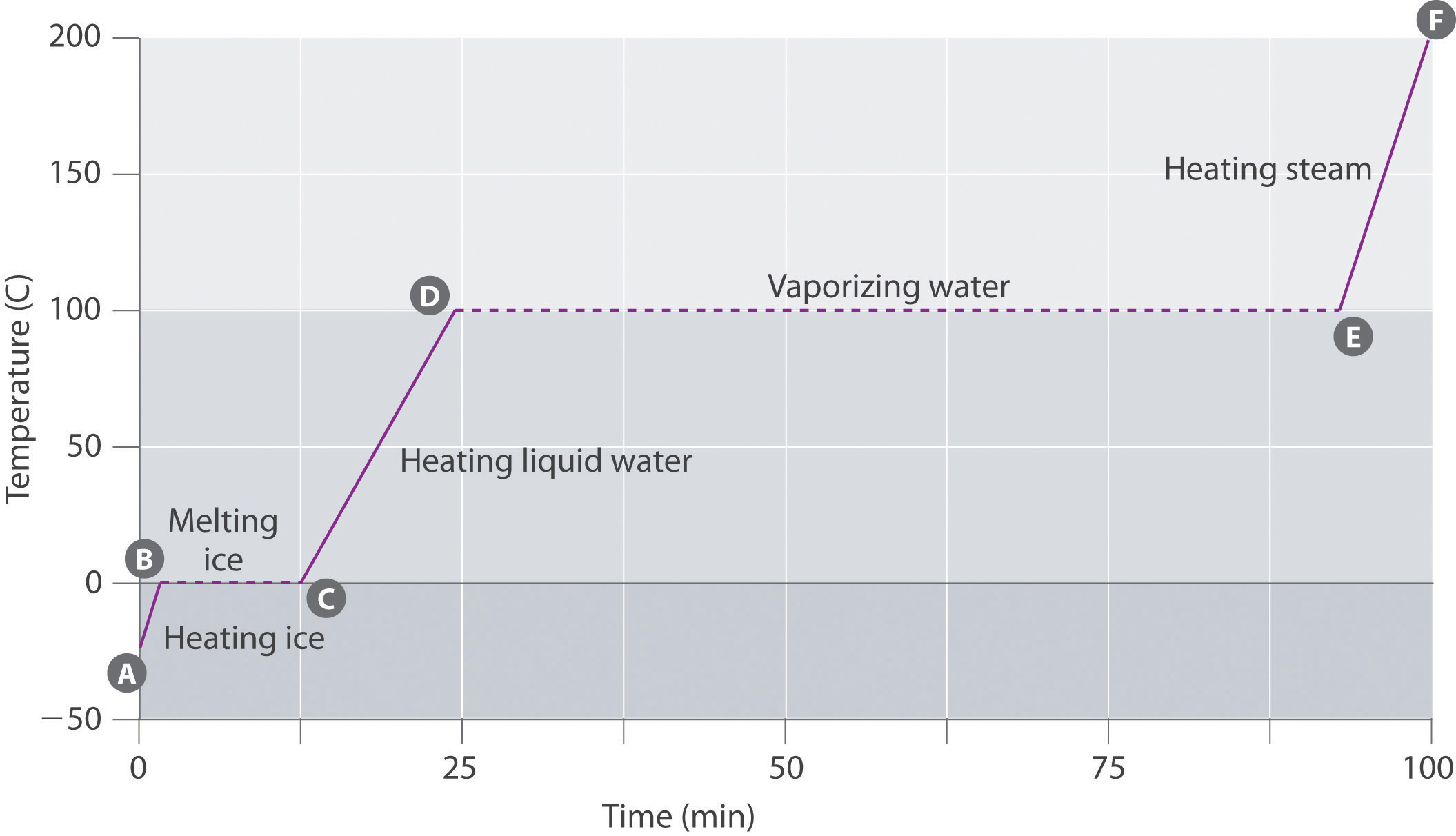

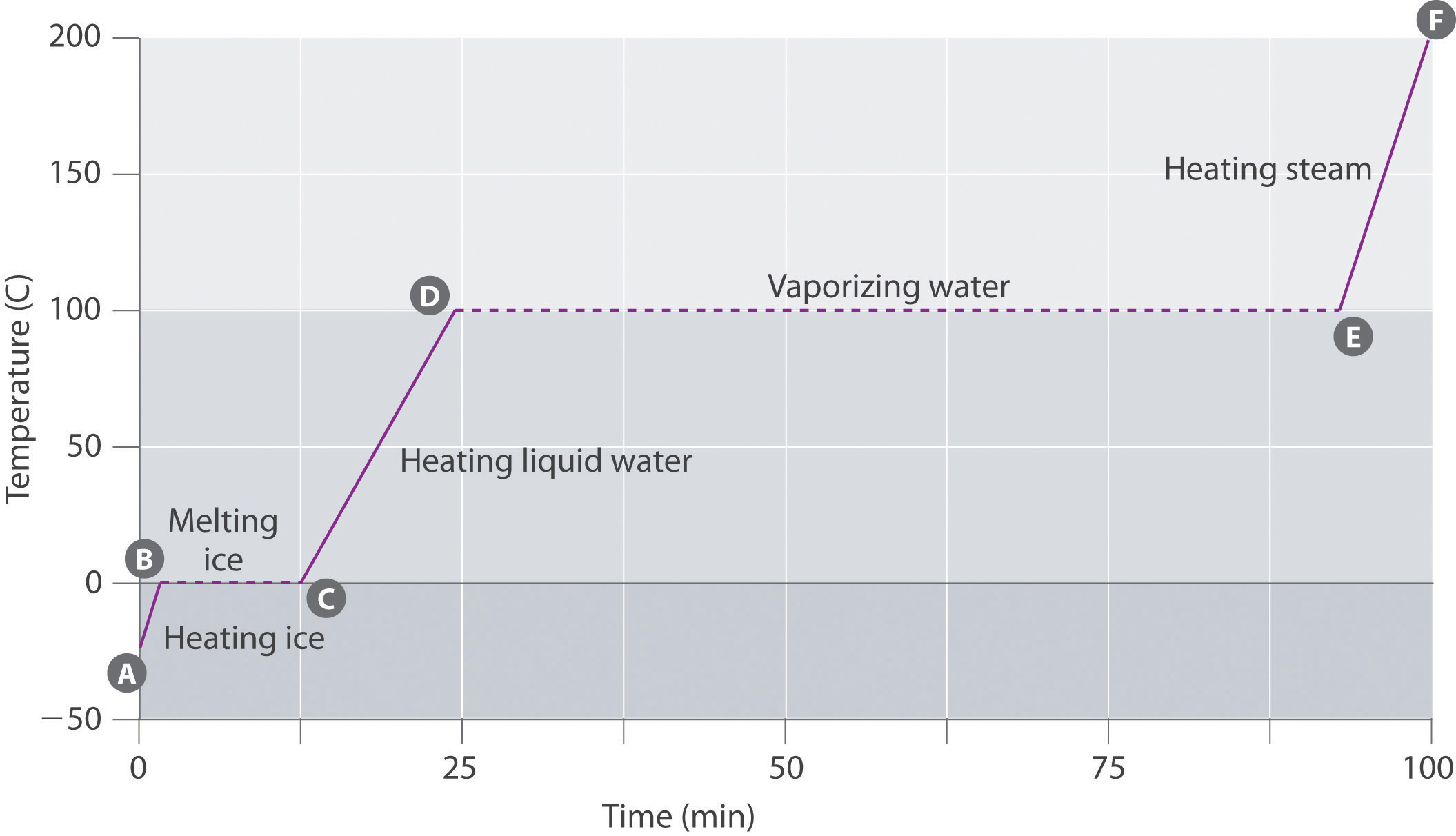

Your own engine has some level of blow-by that lets combustion products into the crankcase oil. That includes water. Older engines let more of those combustion products into the crankcase. And, more water. I have no proof of the rate of dissipation at temperature other than standard chemistry class heat of vaporization curves that every kid sees in high school chemistry.

150F is pretty low and you're driving off/vaporizing the water very slowly at that temperature. You're probably not going to get rid of all the H20 at that temp because the engine is generating it and pumping it into your crankcase as you fly it at low temp. If you do a cross country for several hours, you're probably doing your engine a big favor in driving off the water if the temps are that low, but I couldn't say for sure. 150 is too low. 110 is way too low.

I recommend more RPM in the pattern. Full power and climb at Vx. Climb harder, turn harder, leave your throttle wide open to increase heating. Run as lean as you can without causing icing. It makes pattern work fun.

Next,The most important piece of daily engine maintenance I do is this:

https://flyingsafer.com/2039

In fact, I'm upgrading soon to this:

https://flyingsafer.com/2065

Other than that, I change my oil every 25 hours and use CamGuard Oil additive.

-

Re: Here or Maintenance? Engine quit on final.

Re: Here or Maintenance? Engine quit on final.

Every gallon fuel you burn you generate a gallon of water. It’s all water vapor at that point and most of it exits the exhaust.

A small amount blows by the rings and most of that exits the crankcase vent. If this is cooled to the dew point it condenses into liquid water. I have my crankcase vent insulated to prevent condensation. The real problem happens when you shut down your engine. The residual water vapor in th he crankcase will condense out if your engine cools below the dew point of the water vapor in the crankcase. That is why I use CamGuard.

I installed new cylinders in January of 2019 so I couldn’t run CamGuard. Being concerned about water vapor condensing in the engine I built and installed a crankcase dehydrator. Immediately after shutdown I hooked a vacuum cleaner to the crankcase vent and removed the dipstick t allow ambient air to be pulled thru the crankcase removing the higher vapor content air while I closed up the hangar; about 10 minutes.

I then removed the vacuum cleaner and connected the suction side of the dehydrator to the crankcase vent and pulled the dehydrated air ok’ing out of the dehydrator in to the engine thru the dipstick hole sealed with a rubber cork. The timer was set for two hours which was more than adequate. Initially I measured the dew point of the air exiting the crankcase into the dehydrator to determine the two hours. I abandoned this process when the cylinders were broken in and went back to the cam guard.

Is all this necessary? Probably not, especially in the summer. In Memphis we can see some winter nights with dew points and sensible temperatures that are the same. That was my concern it would occur after a late afternoon flight.

-

Re: Here or Maintenance? Engine quit on final.

Re: Here or Maintenance? Engine quit on final.

Thanks to both of you -- good info!

-

Re: Here or Maintenance? Engine quit on final.

Re: Here or Maintenance? Engine quit on final.

Originally Posted by

brian heidt

Flying in Michigan here with winter kit over oil cooler. 18 Fahrenheit outside and Oil temps stabilized at 150. I don’t have a CHT gage. Never worried about it until this thread. Should I tape part of the cowl inlets? If so what part. Top, bottom inside outside?? I like to do pattern work, so lots of low power settings. Am I damaging my engine ? -Brian in Owosso

Engine operating temperature is another item that is not usually given enough consideration in cold weather. We usually are very cautious about high oil temperature which we know is detrimental to good engine health, while a low oil temperature is easier to accept. The desired oil temperature range for Lycoming engines is from 165˚ to 220˚ F. If the aircraft has a winterization kit, it should be installed when operating in outside air temperatures (OAT) that are below the 40˚ to 45˚ F range. If no winterization kit is supplied and the engine is not equipped with a thermostatic bypass valve, it may be necessary to improvise a means of blocking off a portion of the airflow to the oil cooler. Keeping the oil temperature above the minimum recommended temperature is a factor in engine longevity. Low operating temperatures do not vaporize the moisture that collects in the oil as the engine breathes damp air for normal combustion. When minimum recommended oil temperatures are not maintained, oil should be changed more frequently than the normally recommended 50-hour change cycle. This is necessary in order to eliminate the moisture that collects and contaminates the oil.

-

Re: Here or Maintenance? Engine quit on final.

Re: Here or Maintenance? Engine quit on final.

Hi subsonic and others,

update. Have been flying longer and harder, today WOT for 30 min. 2600rpm indicated, 2800 ft. oAT 10 Fahrenheit. Oil temp never went above 165. Winterszation kit is in, oil cooler is covered. Using cam guard. Changing oil at 25 hours. Am I hurting this engine. Should I cover part of cowl inlet? Personally I don’t really like flying the pattern at 100 and landing no flaps. So not going to fly any harder. Ideas? Thanks Brian

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote